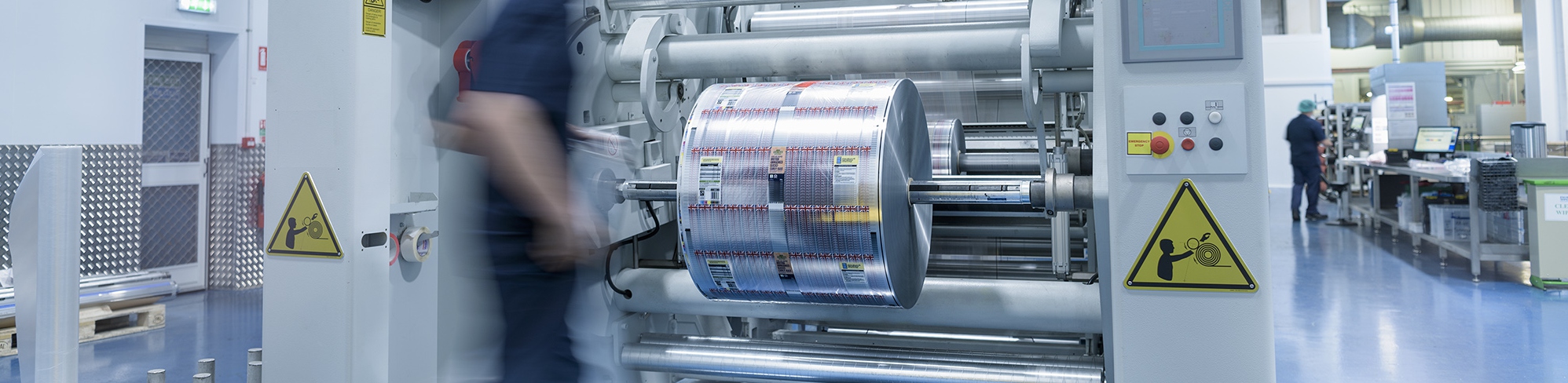

Rotogravure Printing Excellence:

Precision Meets Performance

At the heart of our premium flexible packaging solutions lies the most advanced rotogravure printing technology – engineered to deliver unmatched colors vibrancy,

consistency, and durability.

9 color printing + specialty inks (metallic, fluorescent, soft-touch)

-Real-time defect detection with AI-powered vision system

-400m/min maximum speed for high volume efficiency

-Automated ink viscosity control for batch-to-batch consistency

-Energy-efficient drying system (30% less power vs industry avg.)

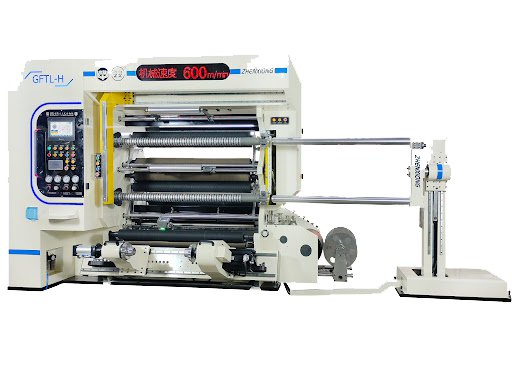

Laminating Technology:

Uncompromising Bond Strength & Clarity

Our fully automated, multi-layer laminating systems redefine durability and precision in flexible packaging. Engineered for complex barrier requirements and

flawless aesthetics, these machines deliver what commodity laminators cannot:

-Peel strength up to 12N/15mm (exceeds FDA 21 CFR requirements)

-Solventless lamination – 100% VOC-free bonding

-In-line corona treatment for perfect adhesion

-Handles aluminum foil, PET, OPP, CPP, Metallized films, etc.